Threading

At Samtec Tools & Accessories Pvt. Ltd., we are proud to offer a comprehensive range of high-performance threading tools engineered for precision, durability, and efficiency across diverse industries.Our innovative product lines are designed to meet the needs of both small-scale machining and heavy-duty industrial operations such as Oil & Gas, ensuring exceptional results in every application.

Whether you require thread turning, indexable mill threading, or specialized thread milling for hardened materials, Samtec delivers solutions that combine cutting-edge technology with proven performance.

FAQs

1. What is threading in machining?

Threading is a machining process used to create helical grooves (threads) on a cylindrical or conical surface, either externally (on bolts) or internally (on nuts). It ensures secure fastening and assembly in mechanical systems.

2. What are the main types of threading methods Samtec offers?

Samtec offers:

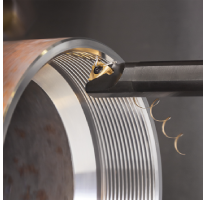

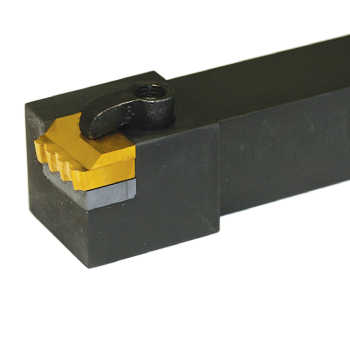

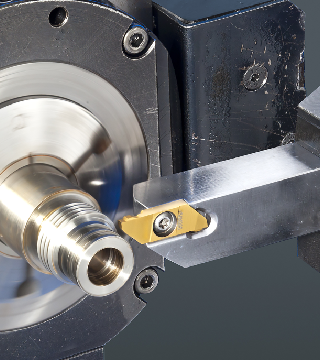

- Thread Turning (external and internal threads using inserts)

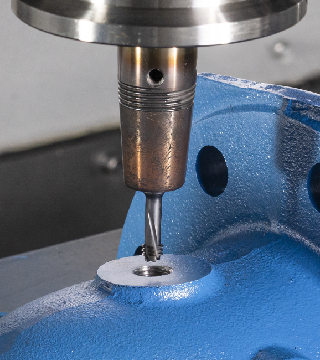

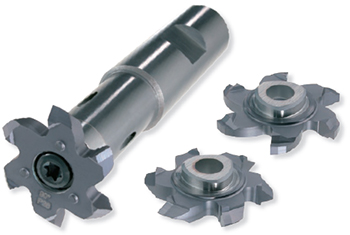

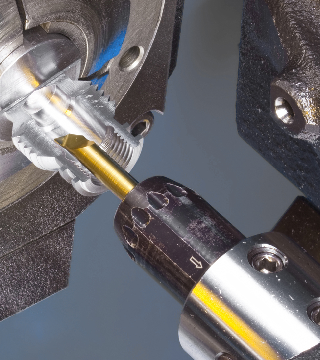

- Indexable Mill Threading (thread milling with replaceable inserts)

- Solid Carbide Thread Milling (for hardened materials)

- Circular Thread Milling (Polymill)

- Threading for Swiss-type lathes (SwissTec & Tiny lines)

3. How to Choose the Right Threading Tool for Your Application

Selecting the appropriate threading tool depends on multiple factors, including material type, thread size, thread form, machine capability, and production volume. Here, we break down the considerations you need to make to choose the best threading tool for your needs.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+