Face Grooving

Face Grooving

Overview

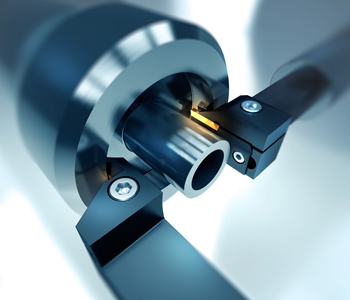

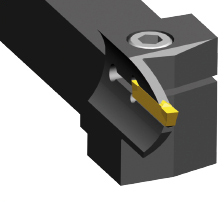

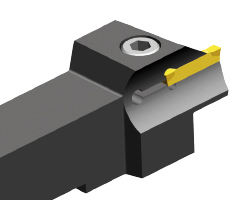

P92-2 and P92-90 Face grooving tools

for the range Ø 25 mm -- Cartridge-system

- Monoblock-system

- P92 2 TMS blade

MONOBLOCK facet

Characteristics

- The strong and rigid tool holder construction, provides for vibration free run and grants production reliability.

- All GripLock P92 inserts fit in the MONOBLOCK face grooving tool holders.

- In case of problems you can just select the most effective chip breaker from the assortment of applicable inserts.

- 40 right hand and 40 left hand different tool holders with shank dimensions 20 mm x 20 mm and 25 mm x 25 mm.,

Technical specifications

- Available width of inserts:

3 mm, 4 mm and 5 mm; 6 mm (optional) - Range of diameters:

25 mm - 450 mm - Depth of cut:

15 mm - 45 mm - Available chip breaker:

14

14 available chip

BTN Parting off chip breaker

Grooved parting off edge with reinforced flanks. The deep and spacious chip-trough gives excellent chip control. Efficient on almost all materials.

BTNG-Finishing

Grooved cutting edge. Horizontal turning edges with parallel chip breakers. The precision ground micrograin insert is recommended especially for heat resistant alloys.

BTNX-Semi finishing

Grooved cutting edge. Horizontal turning edges with parallel chip breakers. The TIN-coated cermet insert is recommended for high speed finishing. The insert can be used universally. The grade KM TILOX is recommended for semi finishing to roughing machining.

ALU chip breaker

Horizontal ground cutting edge. The flat chip chamber conveys chips at high speed.Recommended for: Nonferrous heavy metals, machining steels, thinwalled parts, unstable components and pipes.

IT Classic chip breaker

Horizontal, chamfered parting off edge with reinforced flnks and large chip breaker. To be used universally and especially on interrupted cuts.

CTDS-Super finishing

Chamfered cutting edge and sharply ground turning edges. Excellent chip control even on turning with small cutting depths.

GTNS

- Chip breaker: Especially developed for effective chip flow when face grooving.

- Insert: Developed for machining of stainless and alloys steels.

- Clearance: Especially for face grooving. To be used as well for radial grooving and parting off

MTNS-Roughing

Grooved cutting edge and wave shaped turning edges. Chip control even when machining high alloy steels and stainless steels.

MTNZ-Schruppen

Grooved cutting edge and wave shaped turning edges. Chip control even when machining high alloy steels and stainless steels.

OTXS-Semi finishing

Ground top rake with 0° rake angle. Recommended for cast materials and for customers applications.

RTNG-Finishing

Precision ground full radius insert. Horizontal cutting edge with parallel chip breaker. The micrograin insert is especially recommended for heat resistant alloys.

RTNX-Roughing

Full radius insert. The horizontal cutting edge with its chip breaker rips makes short chips on almost all materials.

VTNS-Roughing to finishing

Horizontal cutting edge with V-shaped chip breaker. Horizontal turning edges with large chip spaces to allow deep cuts. Especially recommended for carbon steels, low alloy steels and free cutting materials.

XTNS-Roughing to finishing

A 9° declining major cutting edge with a reinforcing chamfer and a 24° positive entry to the chip former, achieve excellent chip control especially on difficult to cut materials. The minor cutting edges with 16° positive entry angle achieve efficient profile turning creating clean surfaces. Although the insert has been developed for universal cutting and turning, parting off tests with KM TILOX proved excellent tool life on stainless steels, e.g. 1.4404 (X2 CrNiMo1810). Therefore the insert is also recommmended for stainless steel parting off. The best tool life on parting off hexagon material 1.4571 Ø 38 has been 409 pcs so far. This could be increased to an amazing 678 pcs with the same speeds. (Vc: 60 m/min; f: 0,05 mm/Rev.)DOWNLOAD CATALOGUE

FAQ

1. What are face grooving tools used for?

Face grooving tools are used to create precision grooves on the face of a rotating component, typically in a lathe or CNC machine. These grooves are commonly required in sealing surfaces, O-ring grooves, and retaining features.

2. What is the diameter range for SAMTEC face grooving tools?

SAMTEC’s face grooving tools are designed to handle diameters ranging from 25 mm to 450 mm, making them suitable for both small and large component applications.

3. What insert widths are available?

The available insert widths for face grooving tools are 3 mm, 4 mm, and 5 mm (with 6 mm as an optional width), offering flexibility for various groove dimensions.

4. What is the difference between the P92-2 and P92-90 systems?

Both P92-2 and P92-90 systems are face grooving tool setups within SAMTEC’s offering. The main difference lies in their construction and application-specific capabilities, allowing for optimal chip control, insert rigidity, and compatibility with various cutting depths and materials.

5. What are the advantages of the MONOBLOCK system?

- Vibration-free cutting due to rigid construction

- Compatibility with all GripLock P92 inserts

- Reliable production results

- Quick tool changes and accurate insert re-positioning

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+