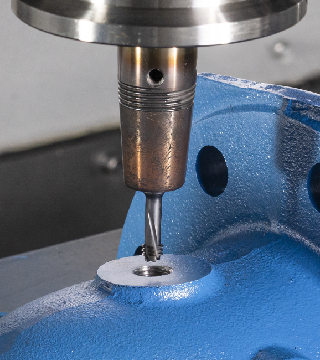

Solid Carbide Threading endmill

Solid Carbide Threading endmill

for Hardened material up to 62HRC

Overview

Samtec’s Solid Carbide Threading Endmills are engineered for high-performance threading operations on hardened materials up to 62HRC. Specifically designed for small diameter, short left-hand cut, these endmills are perfect for internal threading on challenging materials like hardened steel, titanium, stainless steel, and nickel-based alloys.

Our tools are ideal for producing high-precision threads with enhanced surface finishes, improving the quality and performance of your machined components.

Key Features

-

- Smooth Thread Milling: These endmills provide smoother milling of threads, ensuring high-quality finishes and greater performance in difficult materials.

- Enhanced Surface Finish: Designed for superior surface quality, these tools offer excellent thread finishes, reducing the need for secondary operations.

- Threading Range: Available in a range starting from M1.4 x 0.3 in Metric and 1-72 UNF in Unified thread profiles, catering to various threading needs.

Grade SC9839

Our SC9839 grade threading endmills feature ultra-fine carbide grains and a PVD AlTiN coating layer, delivering superior:

-

- Wear Resistance: Withstanding high wear and tear, even during high-speed cutting operations.

- Toughness: Ensuring durability in tough machining environments.

- Cutting Performance: Capable of working at high cutting speeds with medium feeds, ideal for hardened materials and tough alloys.

This grade is particularly suited for use with materials up to 62HRC, including:

-

- Hardened Steels

- Cast Irons

- Titanium Alloys

- Nickel-Based Alloys

- Stainless Steel

Applications

Samtec’s Solid Carbide Threading Endmills are widely used in industries requiring precise, high-performance threading in hard materials, including:

-

- Aerospace Industry: Ideal for creating robust, reliable threads in components exposed to extreme conditions.

- Medical Industry: Perfect for precision threading in medical devices and equipment.

- Die & Mold Industry: Used for creating threads in die and mold tooling materials that require enhanced durability and performance.

Video

DOWNLOAD CATALOGUE

FAQ

1. What is a Solid Carbide Threading Endmill?

A solid carbide threading endmill is a cutting tool used for creating threads in various materials, including hardened steels, stainless steel, titanium, and other tough alloys. It is made of solid carbide for high rigidity, precision, and wear resistance, ideal for high-speed, high-performance threading operations.

2. What materials can these endmills be used on?

Our solid carbide threading endmills are designed to perform exceptionally well on hardened materials up to 62HRC, including:

- Hardened steels

- Cast irons

- Titanium alloys

- Nickel-based alloys

- Stainless steels

3. What thread profiles do these endmills support?

These threading endmills support a variety of thread profiles, starting from M1.4 x 0.3 in Metric threads and 1-72 UNF in Unified threads. This versatility makes them suitable for a wide range of threading applications.

4. What makes the SC9839 grade special?

The SC9839 grade features ultra-fine carbide grains and a PVD AlTiN coating that enhances wear resistance and toughness. This makes the tool ideal for high-speed cutting with medium feeds, ensuring high-performance results on tough materials like hardened steels and alloys.

5. How does the AlTiN coating benefit the tool?

The AlTiN (Aluminum Titanium Nitride) coating provides exceptional wear resistance and allows the tool to withstand the heat generated during high-speed machining. It increases the tool's lifespan and maintains performance even in challenging applications involving high hardness materials.

6. Can these endmills be used for both internal and external threading?

Yes, these solid carbide threading endmills are primarily designed for internal threading applications. However, they can also be adapted for external threading in certain setups, depending on the tool holder and machine configuration.

7. Why choose Samtec for threading tools?

Choose Samtec Tools for high-quality, innovative threading solutions tailored to your needs. With a wide range of products, advanced materials like SC9839 with AlTiN coating, and years of industry expertise, we ensure precise, durable, and efficient tools for sectors like aerospace, medical, and die & mold. Trust Samtec for reliable performance and excellent customer support.