See Other Product

USPOT

USPOT

Overview

Ultimate Back: Redefining Precision in Back Spot-Facing and Counterboring

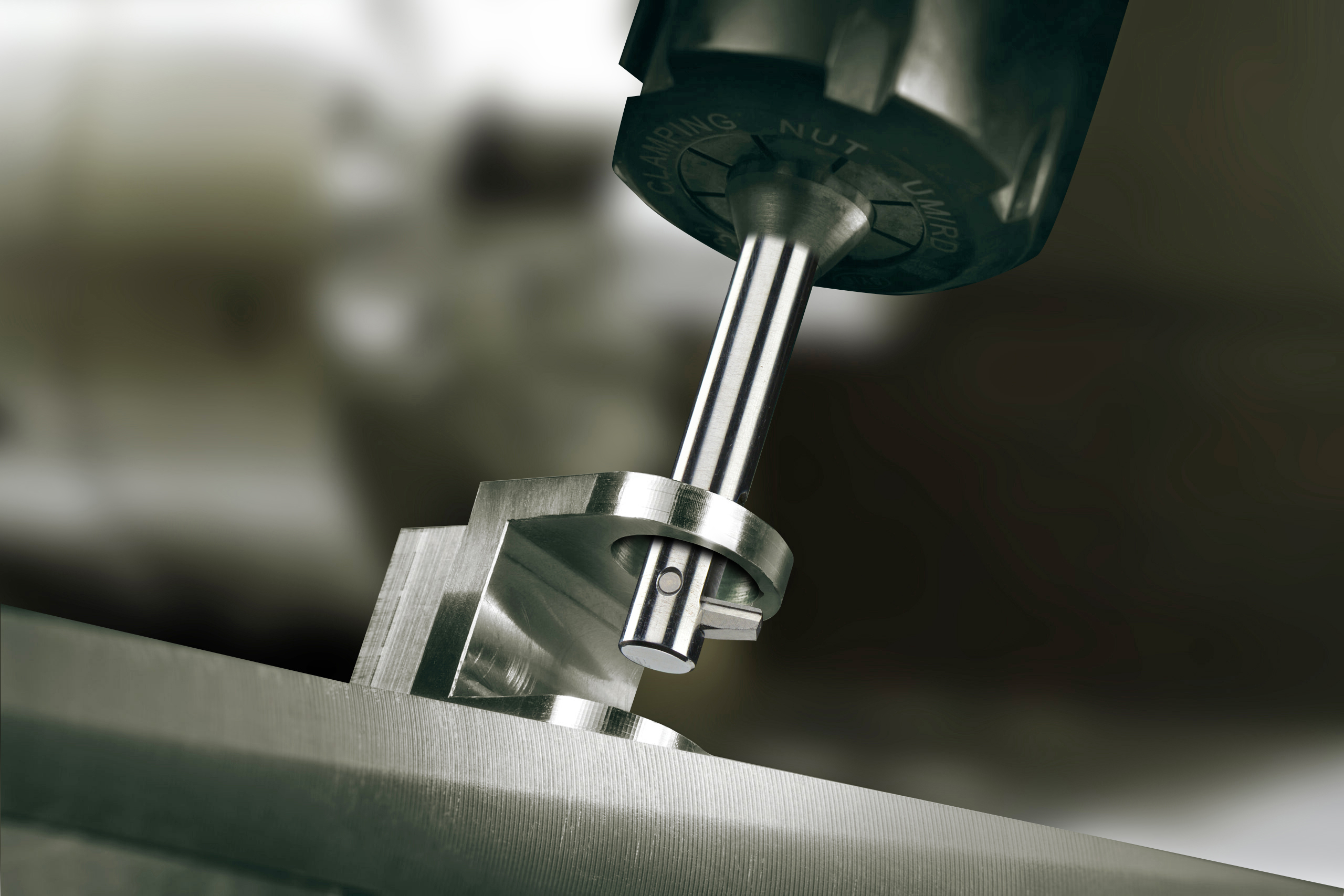

Discover the Ultimate Back – a revolutionary solution engineered by NOGA MT to elevate back counterboring, countersinking, and spot-facing processes to new levels of precision and efficiency. Featuring the innovative combination of UX tool-holders and USPOT/UCHAMF inserts, this cutting-edge system delivers unmatched accuracy and repeatability, making it the ideal choice for industries like aerospace, automotive, medical, and electronics.

What sets Ultimate Back apart is its patented hydraulic mechanism, which utilizes the internal coolant pressure (minimum 20 bar / 300 PSI) to drive the tool’s operation. This clever design ensures precise and smooth insert movement without the need for rotating the workpiece. The result? Faster machining cycles, reduced setup time, and flawless surface finishes—all achieved in a single pass.

Key Features of the Ultimate Back System:

-

-

- Coolant-Powered Hydraulic Precision

The UX tool-holders feature a unique coolant-driven mechanism, eliminating mechanical complexity while delivering smooth, controlled insert deployment. - High-Performance Inserts

The USPOT and UCHAMF inserts are optimized for back spot-facing, counterboring, and countersinking, ensuring reliable results across a wide range of applications. - Single-Pass Machining

Boost productivity by performing complex operations without flipping or repositioning the workpiece. - Automation-Ready Design

Seamlessly integrates into automated CNC and production systems for enhanced manufacturing flexibility. - Versatile Range

UX tool-holders are available in diameters from Ø8 mm to Ø25 mm (0.315–0.984”) and support various insert configurations to match different pilot-hole sizes and machining needs.

- Coolant-Powered Hydraulic Precision

-

Applications:

The Ultimate Back system is tailored for operations where accessing the rear side of a hole is challenging or impossible. It is especially useful in high-precision industries that demand efficiency and reliability:

-

-

- Aerospace Industry

Perfect for complex, lightweight components where flipping the part would compromise structural integrity or introduce delays. - Automotive Manufacturing

Ideal for engine blocks, transmission housings, and other precision-machined parts requiring consistent back counterboring or spot-facing. - Medical Device Production

Enables precise, contamination-free back machining on small, intricate components. - Electronics & Instrumentation

Supports fine machining of enclosures and parts where dimensional tolerance and smooth surface finish are critical. - Heavy Machinery & Equipment

Simplifies processing of large or difficult-to-move parts by eliminating the need to reposition them. - General CNC Machining Shops

A versatile, time-saving addition to any facility handling a wide range of materials and part geometries.

- Aerospace Industry

-

Optimize Your Machining Process with Ultimate Back

Ready to revolutionize your back machining operations? Choose Ultimate Back for the perfect blend of precision, efficiency, and innovation. Backed by NOGA MT’s expertise and the robust DURASHIELD line, this system sets the new industry benchmark.

Browse the full range of UX tool-holders and USPOT inserts on our product page and experience the future of back machining today.

Video

DOWNLOAD CATALOGUE

FAQ

1. What is the Ultimate Back system used for?

The Ultimate Back system is designed for precise back spot-facing, counterboring, and countersinking without needing to flip or reposition the workpiece. It allows single-pass machining on the backside of components.

2. How does the tool operate without rotation or manual actuation?

The system uses a patented hydraulic mechanism powered by internal coolant pressure (minimum 20 bar / 300 PSI), which pushes the insert smoothly into cutting position, eliminating the need for external actuators or complex setups.

3. What industries benefit most from Ultimate Back?

It is especially beneficial in aerospace, automotive, medical, electronics, and general CNC machining, where precision, efficiency, and minimal setup time are crucial.

4. What sizes are available in the UX tool-holder range?

UX tool-holders are available for pilot holes ranging from Ø8 mm to Ø25 mm (0.315–0.984”), covering a wide spectrum of industrial applications.

5. Can I use Ultimate Back on any CNC machine?

Yes, the system is compatible with most CNC and automatic lathes or milling machines that supply sufficient coolant pressure (20 bar or more).

6. Do I need special inserts for this tool?

Yes. The system uses USPOT inserts for spot-facing and UCHAMF inserts for chamfering, both designed to work seamlessly with UX tool-holders.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+