1 cutting edge Parting off

1 cutting edge Parting off

Overview

- Parting off

- Grooving

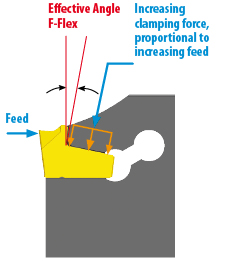

Construction and the way, these perfect grooving and parting off tools fit together

- Loss of center height

- Opening of insert pocket

- Fatigue of material

- Insert creeping

Advantage

- Vibrations = 0

- Positioning in insert pocket is perfect

- Heat rejection improved

- Quick and defined insert change

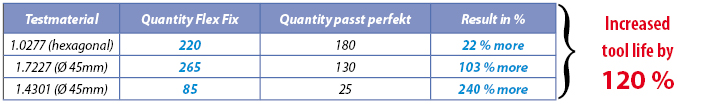

Authentic tests:Parting off

Geometries

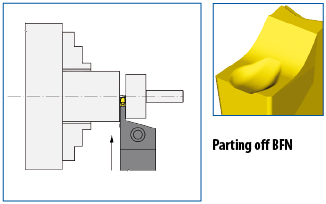

BF Parting off geometry

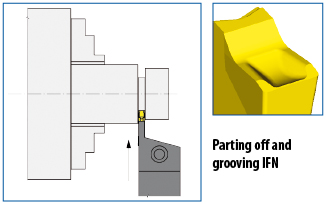

IF geometry

- Alloy steels

- Stainless steels

- Interrupted cuts

SF geometry SUPERNOVA

Recommended for free cutting and low alloy steels and stainless steels, also to be used on unstable machine tools.

IF ALU geometry

Worth knowing

Grooving

Grooving, the major edge cuts a groove

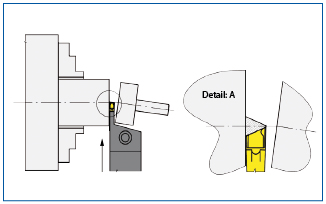

Parting off

The major edge parts off a comonent

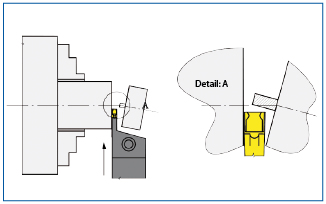

Parting off components leaving a bur

Parting off components without leaving a bur

Flex Fix inserts

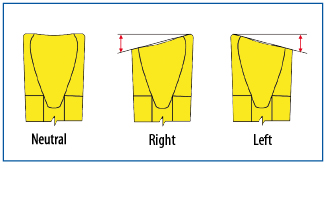

Neutral inserts, inserts with lead angle right and lead angle left

Definition of rotation

View into the spindle

RH or CCW: Workpiece or bar rotates counter clockwise

LH or CW: Workpiece or bar rotates clockwise

DOWNLOAD CATALOGUE

FAQ

1. What are 1 Cutting Edge Parting Off tools used for?

These tools are designed for precise parting off and grooving operations. They use a single cutting edge to separate components from bar stock or to cut grooves with superior accuracy and stability.

2. What makes SAMTEC’s 1 Cutting Edge Parting Off tools different from traditional systems?

- Loss of center height

- Insert pocket loosening

- Material fatigue

- Insert creep

3. What are the advantages of using these parting off tools?

- Zero vibrations during operation

- Perfect insert pocket positioning

- Improved heat dissipation

- Quick and precise insert replacement

- High reliability and consistency

4. What parting-off geometries are available in this system?

- BF Geometry: Reinforced flanks, spacious chip-through. Suitable for most materials.

- IF Geometry: Chamfered edge, ideal for alloy/stainless steels and interrupted cuts.

- SF Geometry (SUPERNOVA): Arc-shaped edge, perfect for unstable machines and soft materials.

- IF ALU Geometry: Sharp, positive geometry for high-speed machining of aluminum and thin-walled parts.

5. How do these tools help in reducing burrs during parting off?

With precise geometry and optimized cutting angles, these tools enable burr-free parting, improving the finish and reducing the need for secondary operations.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+