Thread Turning

Thread Turning

Overview

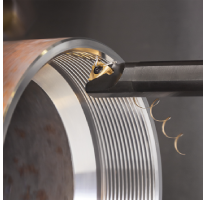

Samtec Tools & Accessories Pvt. Ltd. is proud to offer an extensive range of Thread Turning tools that deliver precision, durability, and high performance for a variety of threading applications. Our Thread Turning product line is widely recognized for its high-quality laydown inserts, designed to meet the threading requirements of most industry standards. We provide a comprehensive selection of inserts, offering both ground profiles and pressed chipformer inserts—ensuring superior thread quality across all applications.

Product Range

Our Thread Turning solutions cater to both external and internal threads with a variety of insert types and grades to match specific operational needs.

We offer:

-

-

- Miniature Inserts: Perfect for threading small bores with diameters as small as 6.4mm, providing exceptional precision for micro-machining tasks.

- Multitooth Inserts: Designed for higher productivity, offering multi-tooth cutting edges for faster machining without compromising on thread quality.

- U-Type Inserts: Ideal for universal thread types, these inserts provide versatility across a wide range of threading profiles.

-

High-Performance Inserts

Samtec’s Thread Turning inserts come in the premium SC7819 grade, engineered with a Superb Chipping Resistance and coated with TiAlN (Titanium Aluminum Nitride). This coating ensures:

-

-

- High Wear Resistance, allowing the tool to withstand even the most demanding materials.

- Superior Performance across a broad range of materials, including ISO P15-P30, M20-M30, K20-K40, S15-S30, and H20-H30 categories.

-

The SC7819 grade inserts are designed to deliver optimal cutting performance in a variety of industries, such as automotive, aerospace, and general manufacturing.

Tool Holders and Inserts

In addition to our premium inserts, Samtec offers a comprehensive collection of threading tool holders. These are designed for both external and internal threading operations, ensuring rigidity and stability during machining. Our tool holders come in various configurations, including those with carbide shanks for applications requiring small diameters and deeper internal threads.

Applications and Benefits

Samtec’s Thread Turning solutions are perfect for industries that demand precision threading, such as:

-

-

- Automotive Manufacturing: For producing high-quality threads in critical components.

- Aerospace: Ensuring the highest performance in high-stress environments.

-

General Engineering: Offering versatile solutions for everyday manufacturing needs.

-

Video

DOWNLOAD CATALOGUE

FAQ

- What is Thread Turning?

Thread turning is a machining process where a cutting tool is used to create threads on the outer or inner surface of a workpiece. It’s typically done using lathe machines and is ideal for creating high-precision threads in both large and small diameters.

- What types of threading tools does Samtec offer?

Samtec offers a wide range of thread turning tools including:

-

- Miniature Inserts for small bore threading (as small as 6.4mm)

- Multitooth Inserts for higher productivity

- U-Type Inserts for versatile applications across different thread profiles

- External and Internal Tool Holders for various threading operations

- What materials can Samtec’s thread turning tools handle?

Our SC7819 grade inserts, coated with TiAlN, are designed to handle a wide variety of materials, including:

-

- ISO P15-P30 (steel and cast iron)

- M20-M30 (stainless steel)

- K20-K40 (hard materials like tool steels)

- S15-S30 (high-temperature alloys)

- H20-H30 (hardened materials)

- How do I choose the right threading tool for my application?

Choosing the right tool depends on factors like:

-

- Material type: Ensure the tool’s grade and coating match the material you're working with.

- Thread size: Select the correct insert type (miniature, multitooth, U-type) based on your threading requirements.

- Machining conditions: Consider cutting speed, feed rates, and machine capabilities when selecting your tool.

- What is the benefit of using multitooth inserts?

Multitooth inserts allow for faster cutting operations, making them ideal for high-volume threading jobs. They provide consistent thread quality and improve productivity by reducing cycle times.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+