SWISSTEC

SWISSTEC

Overview

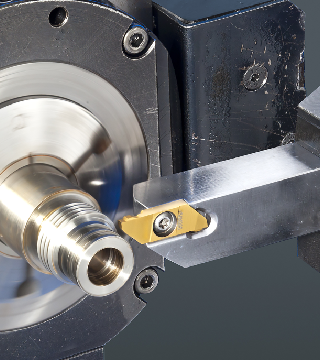

SwissTec offers a high-performance product line designed for Swiss-type and sliding head lathes, specializing in machining small parts across industries such as medical and aerospace. The Grade SC4849, featuring a TiAlN+TiN PVD coating, ensures exceptional durability and wear resistance. This advanced coating performs well on a variety of materials, including steels, high-temperature alloys, stainless steel, and hardened steel. It is ideal for applications across a broad range of ISO material grades, such as P20-P50, M20-M40, K15-K40, S15-S25, H20-H30, and N05-N25.

SwissTec tools excel in challenging machining conditions, particularly during interrupted cuts, offering long tool life and consistent performance. The inserts can be indexed without removing screws, reducing downtime and improving productivity. This feature enables quick insert replacement, ensuring your operations stay efficient.

SwissTec provides versatile inserts for multiple applications, including grooving, parting, turning, back turning, and threading (partial and full profile), making them suitable for a wide variety of machining needs. Tool holders are available in multiple shank sizes (8mm, 10mm, 12mm, and 16mm), ensuring compatibility with different machine setups.

Designed for precision, efficiency, and minimal downtime, SwissTec tooling solutions are ideal for industries requiring high-quality, small part machining.

DOWNLOAD CATALOGUE

FAQs

1. Why should I choose Samtec tools for my SwissTec tooling operations?

Samtec tools are designed to enhance the performance and precision of SwissTec tooling systems. With advanced engineering, high-quality materials, and innovative features, Samtec tools offer exceptional durability, reduced downtime, and superior results in high-demand machining operations. Their compatibility with SwissTec products ensures reliable, high-performance solutions for both small and large-scale production.

2. What makes SwissTec tools ideal for Swiss-type and sliding head lathes?

SwissTec tools are designed specifically for Swiss-type and sliding head lathes, making them perfect for machining small parts in industries such as medical and aerospace. The advanced TiAlN+TiN PVD coating on the inserts ensures high durability and resistance, ensuring precise and efficient machining.

3. Which materials can SwissTec tools handle effectively?

SwissTec’s Grade SC4849 tools, with their TiAlN+TiN coating, are suitable for a wide range of materials, including steels, stainless steel, high-temperature alloys, and hardened steel. They are ideal for machining materials in ISO grades P20-P50, M20-M40, K15-K40, S15-S25, H20-H30, and N05-N25.

4. How do SwissTec tools improve productivity and reduce downtime?

SwissTec tools feature a unique insert indexing system that allows for easy replacement without removing the screw. This reduces downtime significantly, helping to improve overall productivity and minimize tool change time in high-volume machining operations.

5. Can SwissTec tools be used for different machining applications?

Yes, SwissTec offers a wide variety of inserts for applications such as grooving, parting, turning, back turning, and threading (both partial and full profiles). This versatility makes SwissTec tools suitable for a broad range of tasks in small part machining.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+