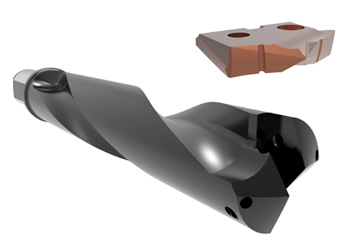

T-A & Gen 2 T-A Drills

T-A & Gen 2 T-A Drills

Overview

- Notch Point® Geometry improves stability, hole straightness and reduces thrust.

- Web Thin reduces thrust and increases point strength allowing greater reliability.

- Helical Margin increases drill stability.

- Helical flute improves tool life.

- Coated in Allied’s proprietary AM200® coating.

- Corner clip for effective heat dispersion helping to increase tool life.

DOWNLOAD CATALOGUE

FAQ

1: What are T-A and GEN2 T-A drills used for?

T-A and GEN2 T-A drills are advanced drilling tools designed for high-performance drilling applications, especially through-holes. They offer excellent stability, reduce cutting forces, and enhance hole quality across various materials.

2: What is the advantage of the GEN2 T-A drill over the standard version?

The GEN2 T-A features improved geometry like Notch Point and Web Thin design, which significantly improves hole straightness, reduces thrust force, and increases reliability during operation.

3: What is the AM200 coating, and why is it beneficial?

The AM200 coating is Allied’s proprietary wear-resistant coating applied on GEN2 T-A inserts. It enhances heat resistance, reduces friction, and increases the overall tool life, especially in demanding machining conditions.

4: How does Notch Point Geometry help in drilling?

Notch Point Geometry enhances drill stability, improves straightness of the hole, and lowers the thrust needed, making it especially effective in difficult-to-machine materials.

5: What materials are T-A and GEN2 T-A drills suitable for?

These drills are ideal for a wide range of materials including steel, cast iron, stainless steel, and other alloys. Their design and coating allow for efficient chip formation and extended tool performance.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+