Multicut 4

Multicut 4

Overview

- Parting off and grooving

- Threading

- Precision grooving

- Full radius grooving

- Special profiles

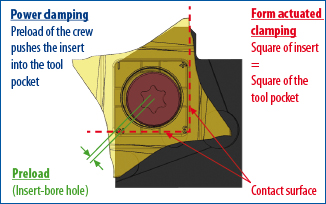

- Perfect power and form actuated clamping.

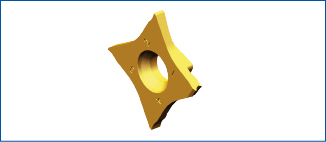

- Reinforced solidity of insert suppresses vibrations. Achieves high and consistant tool life. Maintains reliability on cutting operations.

- Reinforced area of the cutting edge grants stability.

- In case a cutting edge is damaged all other edges can be used independently.

- Precise re-positioning when changing cutting edges.

- Fast and safe fixing in pocket.

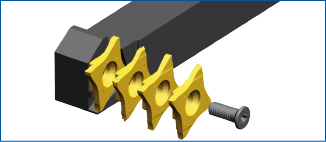

- Only 1 insert pocket for many inserts for different cutting operations.

- New cutting geometry!

DOWNLOAD CATALOGUE

Video

FAQ

1. What are multi-edge grooving tools?

Multi-edge grooving tools feature multiple cutting edges on a single insert. When one edge wears out, others can be used—enhancing tool life, efficiency, and cost-effectiveness for grooving and parting applications.

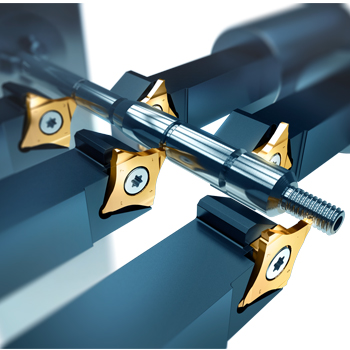

2. What is the MULTICUT 4 system by SAMTEC?

MULTICUT 4 is SAMTEC’s advanced grooving and cutting system that utilizes segmented, vertically positioned inserts. It offers superior clamping, vibration control, and edge stability—making it ideal for high-precision grooving, threading, and profiling operations.

3. What machining operations can be done with MULTICUT 4 tools?

-

- Parting-off

- External/internal grooving

- Precision threading

- Full radius grooving

- Special profile machining

4. How do MULTICUT 4 inserts reduce vibration during machining?

The inserts are engineered with reinforced edge areas and solid clamping geometry. This suppresses vibrations even under heavy loads, ensuring smoother cutting, longer tool life, and improved surface finish.

5. What happens if one cutting edge on the insert is damaged?

If one cutting edge is damaged, you can simply rotate or index the insert to use the next sharp edge. All cutting edges on MULTICUT 4 inserts are independent and usable, maximizing productivity.