Polymill

Polymill

Overview

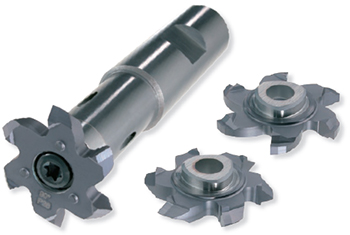

SAMTEC’s Polymill circular milling tools are engineered to provide outstanding performance in deep thread milling applications. Featuring a polygonal insert seat and six cutting edges, these tools are designed to handle deep threads and high chipping volumes with ease and efficiency.

The new generation of Polymill circular cutters offers an array of benefits that improve both the economy and quality of your machining processes.

The polygonal connection between the insert and cutter body ensures better tool stability, resulting in:

-

- Longer Tool Lifetimes: The robust design ensures durability and extended tool life.

- Higher Chipping Volume: Enhanced cutting capabilities lead to increased productivity.

- Higher Feeds: Achieve greater cutting efficiency with higher feed rates.

- Shorter Machining Times: Reduce cycle times, increasing overall production efficiency.

Polymill tools are ideal for plunge cuts, guard ring slots, O-ring slots, and internal threads (including Metric Internal Threads to DIN, Whitworth Threads, and special recesses). These versatile tools are designed for precision milling in components with complex geometries.

Available Variants:

-

- P16, P20, and P26: These are the three basic types of Polymill tools, available in various shank and insert dimensions to meet diverse applications.

- Carbide Options: For added durability, Polymill tools are available in carbide variants with a tool-steel head, ensuring both strength and flexibility.

Polymill's cutting-edge design and varied tool lengths make it the perfect solution for complex machining tasks, ensuring high-quality, cost-effective results in a wide range of industrial applications.

Video

DOWNLOAD CATALOGUE

FAQs

1. What are the main benefits of using SAMTEC's Polymill Thread Milling Tools?

SAMTEC’s Polymill tools offer enhanced precision, longer tool lifetimes, and higher chipping volume. The polygonal insert seat improves the overall machining process by offering higher feeds, shorter machining times, and improved tool stability, which leads to higher efficiency and cost savings.

2. What types of threads can be milled using the Polymill tools?

Polymill tools can be used to mill metric internal threads according to DIN standards, Whitworth threads, and other special recesses. These tools are versatile and suited for a range of thread profiles, making them ideal for various industrial applications.

3. Are the Polymill tools suitable for deep thread milling?

Yes, Polymill tools are specifically designed for deep thread milling, thanks to their robust construction and polygonal insert seat, which allows them to handle high chipping volumes without compromising on precision or performance.

4. What materials are the Polymill milling cutters made of?

The Polymill milling cutters come in carbide variants with a tool-steel head, which combines the strength of tool steel with the durability of carbide. This ensures both robustness and versatility for a wide range of applications.

5. What are the different types of Polymill tools available?

SAMTEC offers three primary types of Polymill tools—P16, P20, and P26. Each type is available with different shank and insert dimensions, allowing for a flexible and scalable solution for a variety of thread milling tasks. These options help extend the application scope and improve machining flexibility.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+