Gen3 Sys

Gen3 Sys

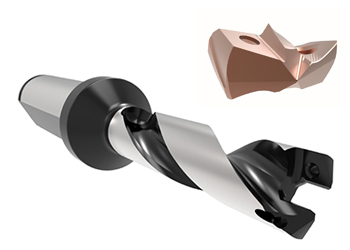

Overview

Features and Benefits

- The unique geometry of the GEN3SYS® Drilling System enables excellent chip control while drilling

- The GEN3SYS® High Penetration Drilling System has a highly precise locating pad for absolute repeatability and reductions in TIR.

- The proprietary AM200® coating increases tool life up to 50% above competitors premium coatings.

- GEN3SYS® Replaceable Tip Drilling System is backed by a highly experienced technical staff

- The unique design of the GEN3SYS® High Penetration Drilling System increases hole quality, surface finish, and true position when compared to other competitive products

- The helical margin design of the GEN3SYS® enables maximum durability and stability when cutting forces are applied

- Diameter Range: 0.4724” – 1.2594” (12,00mm – 31,99mm)

DOWNLOAD CATALOGUE

FAQ

1. What is the GEN3SYS® Drilling System used for?

The GEN3SYS® Drilling System is ideal for high-speed, high-precision drilling in industrial, automotive, and aerospace sectors.

2. How is the GEN3SYS® Drill different from standard drills?

It provides up to 35% faster penetration and 50% longer tool life due to advanced geometry, locating pads, and AM200® coating.

3. What are the key features of GEN3SYS® Drills?

-

- Excellent chip control

- High hole quality and surface finish

- Reduced TIR and repeatability

- Durable helical margin design

- Replaceable tip compatibility

4. What is the role of AM200® coating in GEN3SYS® drills?

The AM200® coating improves heat resistance and wear properties, extending tool life significantly.

5. What diameter range is supported by GEN3SYS® Drills?

From 0.4724” to 1.2594” (12.00 mm to 31.99 mm), supporting various drilling needs.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+