Hard material machining

Hard material machining

Overview

Inserts with efficient chip breakers and special coating for:

- Machining hardened materials

- Hard materials

- Exotic and tempered materials

Definition

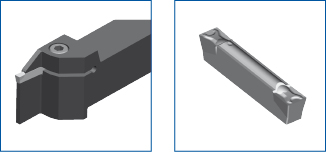

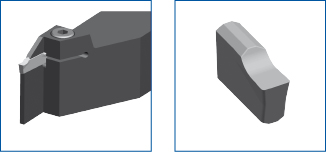

Grooving and

P92 System

P92 S System

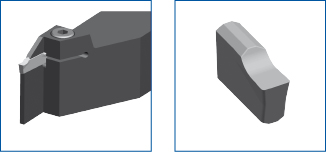

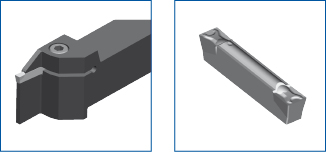

Grooving and parting off

P92 System

P92 S System

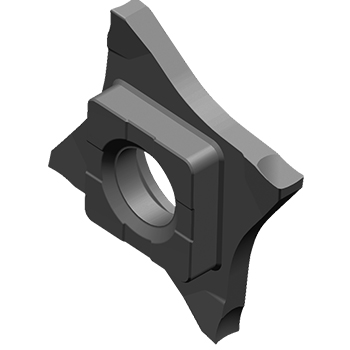

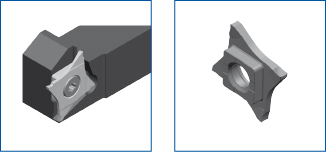

M92 Q MULTICUT 4 system

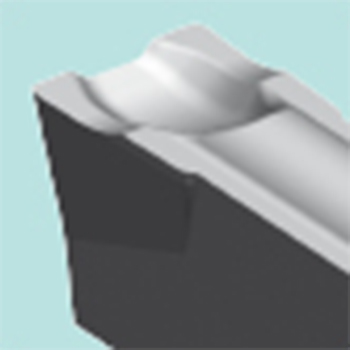

HARDLOX 2

- Coating type: Super Nitrid

- Layers: Nanocomposite, AITixN

The multi layer coating HARDLOX 2

has been developed to machine especially hardened materials. This most advanced coating represents the current state of the art. It is now possible to machine hard materials with a hardness of more than 50 HRS (Rockwell hardness). The coating layer consists of a micro crystalline structure.DOWNLOAD CATALOGUE

FAQ

1. What is hard material machining?

Hard material machining refers to the cutting and shaping of materials with a Rockwell hardness of 54 HRC or more. These include hardened steels, exotic alloys, and tempered metals that are extremely challenging to machine without specialized tools and coatings.

2. Which inserts are suitable for hard material machining?

Samtec offers specially designed inserts with efficient chip breakers and advanced coatings—like HARDLOX 2—for stable performance in hard turning, grooving, and parting-off operations. These inserts provide excellent wear resistance and heat stability under extreme cutting conditions.

3. What is the recommended starting speed and feed for hard material machining?

Due to the high stress placed on the cutting edge and tool holder, it's recommended to start at lower speeds, feeds, and depths of cut when machining hard materials. This helps reduce tool wear and prevents early failure.

4. What is the HARDLOX 2 coating, and how does it help?

HARDLOX 2 is a multilayer nanocomposite coating made from Super Nitrid and AlTiXN. Its micro-crystalline structure enables efficient machining of materials with hardness levels exceeding 50 HRC. It increases tool life and provides excellent thermal and wear resistance.

5. What are the differences between the P92 and P92 S systems?

Both the P92 and P92 S systems are engineered for grooving and parting hard materials. The P92 S system offers enhanced rigidity and optimized chip control, making it ideal for more demanding applications where stability and tool life are crucial.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+