Tailor made solutions

Tailor made solutions

Overview

When and why should tailor made solutions be

- when standard tools are not efficient

- general cost saving measures

- to reduce production time

- to save on tool costs

Our Strengths

- Qualified service

- Specified quotations

- Fair prices

- Production on most advanced machine tools

- Short delivery times

Tailor made inserts

Individual precision on each corner

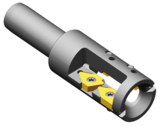

Special tool holders

Sophisticated solutions for your requirements

DOWNLOAD CATALOGUE

FAQ

1. What are tailor-made or special grooving tools?

Tailor-made grooving tools are custom-designed cutting tools built to suit unique machining needs. These tools are crafted to handle non-standard profiles, special materials, or specific operations that cannot be addressed by standard grooving tools.

2. When should I opt for tailor-made grooving tools?

- Standard tools are inefficient

- Your component has a unique profile

- You're aiming to reduce cycle time

- You want to lower overall tool costs

- You’re machining exotic or hardened materials

3. Can SAMTEC design grooving tools as per my part drawing or application?

Yes. SAMTEC specializes in creating grooving tools customized to your technical drawing or application requirements. Our design team ensures precision and durability in every custom tool we manufacture.

4. Are tailor-made grooving tools more expensive than standard ones?

Not always. Although initial costs may be slightly higher, tailor-made tools offer long-term savings through better performance, longer tool life, reduce cycle time and higher productivity.

5. How long does it take to manufacture and deliver custom grooving tools?

Delivery depends on the complexity of the tool, but thanks to our advanced production facility, most custom grooving tools are delivered within a few business days.

6. What customization options are available for special grooving tools?

- Tailor-made inserts with special coatings

- Unique chip breaker designs

- Customized tool holders and shank sizes

- Precision clamping systems

- Specific geometries for parting, turning, or face grooving

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+