Trimill

Trimill

Overview

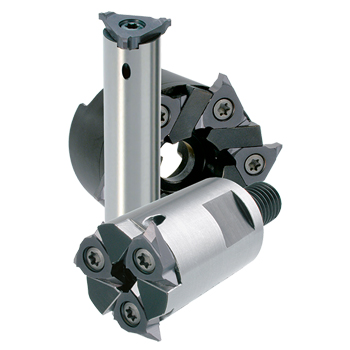

Circular Milling Tools for Contours and Threads

The circular milling principle allows outside and inside contours to be manufactured to individual requirements on all CNC machining centers and milling machines. High efficiency is achieved by short machining times, extended tool life, and by reducing or eliminating with expensive special tools.Blind holes can be tapped practically to the base without under-cutting. The use of uniform pitches also reduces storage and purchasing costs. As long as maximum dimensions are maintained, insert profiles can be customized.

- High Precision Free Contours

- High-Precision Plunge Cuts

- True-to-Gauge Threads can be executed

Video

DOWNLOAD CATALOGUE

FAQ

1. What is the Trimill circular milling system?

The Trimill system by SAMTEC TOOLS is a high-precision circular milling solution designed for machining external and internal contours, plunge cuts, and threads using CNC machining centers and milling machines. It is ideal for applications requiring accuracy, flexibility, and cost efficiency.

2. What are the benefits of using Trimill circular milling tools?

- Shorter machining times

- Extended tool life

- Lower tool inventory cost

- Ability to customize insert profiles

- High-precision contour and thread machining

- Efficient blind hole tapping with minimal undercut

3. What kind of contours can Trimill tools produce?

Trimill tools can machine both including complex geometries. They’re suitable for precision threading & grooving with consistent results.

4. Can Trimill be used for thread milling in blind holes?

Yes. Trimill enables thread milling in blind holes practically down to the base without the need for undercutting. This makes it ideal for high-precision applications.

5. Are the inserts in the Trimill system customizable?

Absolutely. Insert profiles can be customized to meet specific application needs, provided the maximum tool dimensions are maintained.

6. What types of machines are compatible with Trimill tools?

Trimill tools are designed to work seamlessly with all CNC machining centers that support circular interpolation.