MICROTEC

MICROTEC

Tools For Small Part Machining Tools

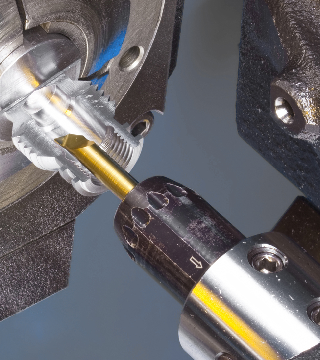

Samtec MicroTec brings you advanced tools for internal machining of miniature parts, catering to industries such as aerospace, medical, and miniature components. With the ability to work on parts starting from an internal diameter of just 0.6mm, these tools provide exceptional performance and precision.

Featuring cutting-edge carbide inserts and versatile tool holders, Samtec MicroTec tools are engineered to meet the demands of modern small part machining.

Key Features of Samtec MicroTec Tools:

-

- Advanced Insert Geometries: Samtec MicroTec tools come with various cutting geometries that support a wide range of internal machining applications.

- Precision and Versatility: Perfect for internal turning, chamfering, profiling, boring, grooving, and threading—all at miniature dimensions with high precision.

- Coolant-Through Technology: Integrated coolant-through inserts ensure optimal chip control and longer tool life by keeping the cutting zone cool during operation.

- High-Quality Materials: The SC5819 grade carbide inserts, coated with TiAlN, offer superior wear resistance, making them suitable for a broad spectrum of materials, from ISO P15-P30 to H20-H30.

Applications:

-

- Internal Turning & Chamfering

- Profiling and Boring

- Internal Turning and Chamfering Near Blind Holes

- Back Turning

- Internal Grooving & Full Radius Internal Grooving

- 45° Chamfering & Back Chamfering

- Pre-Parting & Full Profiling

- Partial Profile Threading

- Face Grooving & Round Profile Face Grooving

- Deep Face Grooving

MITECH Holders for Optimal Precision

Samtec MicroTec integrates MITECH holders with its tools to offer even more flexibility and precision. The MITECH MG Double-Sided Holders allow for mounting two different insert sizes on each side, while the MITECH A holders provide extremely high clamping repeatability (as low as 0.005mm), ensuring consistent results and optimal tool stability.

-

- Coolant Holes: These holders also feature coolant holes, ensuring that coolant reaches the cutting zone effectively, improving tool longevity and efficiency.

- Additional Clamping Options: The holders are equipped with clamping screws located on top to provide additional clamping stability during machining.

Video

DOWNLOAD CATALOGUE

FAQs

1. What are the key industries that benefit from Samtec MicroTec tools?

Samtec MicroTec tools are highly suitable for industries where miniature parts with precise internal dimensions are required, such as the aerospace, medical, and miniature component industries.

2. What types of machining applications can Samtec MicroTec tools perform?

Samtec MicroTec tools are designed for a wide array of internal machining applications, including turning, chamfering, profiling, boring, grooving, and threading—all at miniature dimensions starting from 0.6mm internal diameter.

3. How do the coolant-through inserts benefit the machining process?

The coolant-through inserts in Samtec MicroTec tools supply coolant directly to the cutting edge, improving chip control, reducing tool wear, and enhancing tool life by maintaining an optimal cutting temperature throughout the machining process.

4. What materials are compatible with Samtec MicroTec inserts?

The SC5819 grade carbide inserts, with TiAlN coating, are ideal for a wide range of materials, including ISO P15-P30, M20-M30, K20-K40, S15-S30, and H20-H30. These inserts offer excellent wear resistance, making them suitable for various industrial applications.

5. What advantages do MITECH holders offer with Samtec MicroTec tools?

MITECH holders provide high clamping repeatability (up to 0.005mm), ensuring precise and consistent machining. They also feature coolant holes for better coolant supply, which improves tool life and cutting efficiency. The double-sided holders offer flexibility by allowing the use of different insert sizes on each side.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+