See Other Product

UCHAMF

UCHAMF

Overview

UCHAMF: Advanced Back Countersinking & Chamfering Inserts from NOGA MT

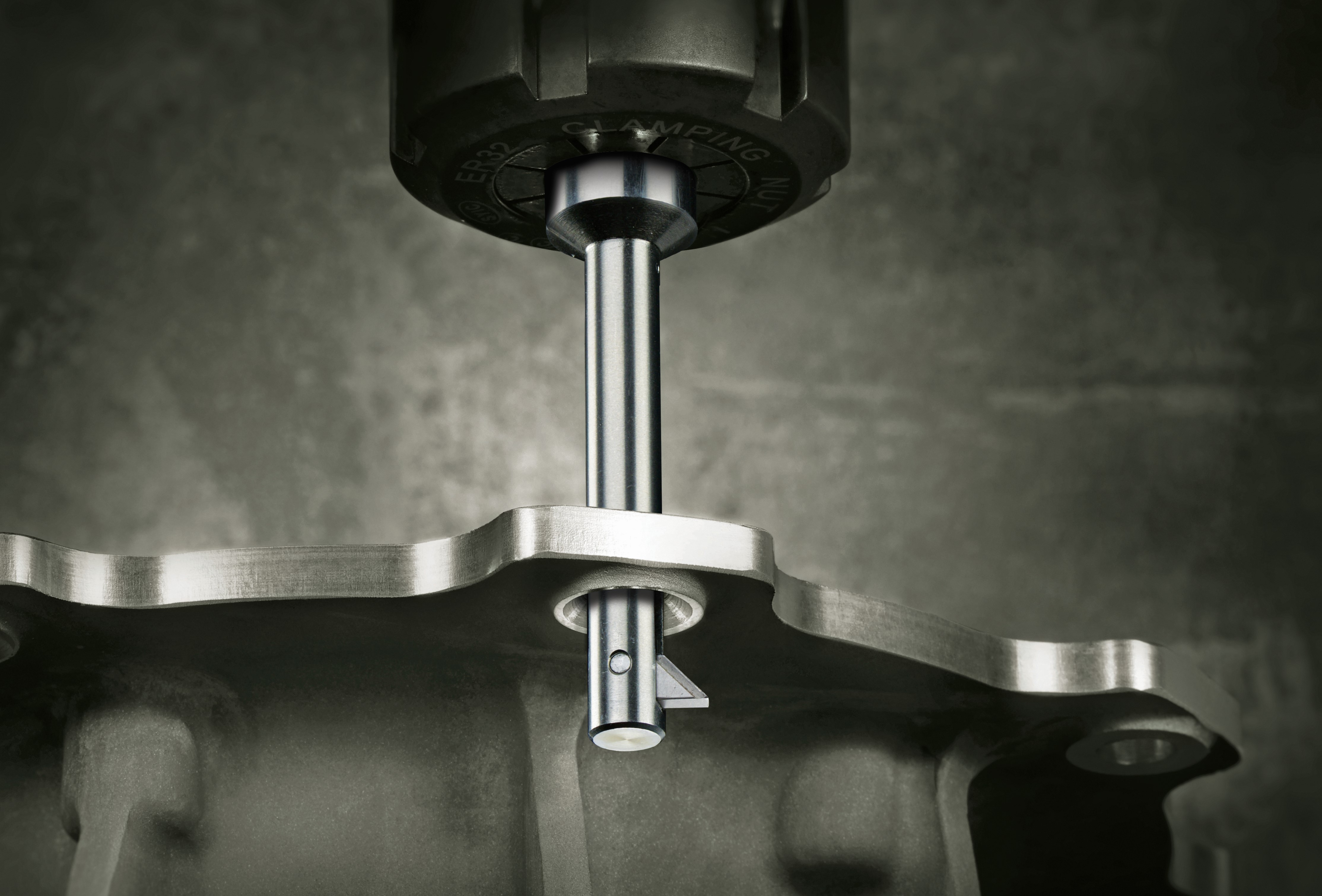

Experience unmatched machining precision with UCHAMF inserts—engineered for accuracy, durability, and performance. Designed for integration with the Ultimate Back (UBACK) system by NOGA MT, UCHAMF inserts are your go-to solution for back countersinking and back chamfering applications in challenging industrial environments.

At Samtec, we bring you cutting-edge tooling solutions that transform how you approach back counterboring. The UCHAMF insert series, when paired with the innovative

Why Choose UCHAMF Inserts?

Precision Engineering for Perfect Back Chamfers

UCHAMF inserts are crafted to perform back countersinking and chamfering with extreme precision. They eliminate the need for workpiece rotation and deliver flawless results in a single pass—reducing cycle time and improving overall efficiency.

DURASHIELD Coating for Maximum Tool Life

Built under NOGA MT’s DURASHIELD premium standard, UCHAMF inserts deliver outstanding strength, heat resistance, corrosion protection, and wear durability. These inserts undergo a passivation process, ensuring they maintain peak performance even under the most demanding machining conditions.

Seamless Integration with UX Tool-Holders

UCHAMF inserts are designed to pair specifically with the UBACK line of UX hydraulic tool-holders. These holders use your machine’s internal coolant pressure (minimum 20 bar / 300 PSI) to control insert movement with hydraulic precision—ensuring stable, repeatable cutting action.

UCHAMF Product Features

-

-

- Available in 82° and 90° countersink angles to meet diverse application needs

- Optimized for a wide range of pilot holes: diameters from Ø8 mm to Ø25 mm

- Eco-friendly corrosion resistance with no additional coatings required

- Easy insert replacement—uses one type of clamping screw without the need for special jigs

- Compatible with automated systems and CNC machining setups

- Superior chip evacuation for cleaner cuts and smoother operations

-

Each UCHAMF insert series is matched to a corresponding UX tool-holder series (B to G), ensuring perfect alignment and optimal performance. Whether you're working on stainless steel, titanium, or other demanding materials, UCHAMF delivers reliability and consistency you can count on.

Applications & Industries

-

-

- Back countersinking in aerospace components

- Back chamfering for automotive engine parts

- Precision medical device machining

- Electronic hardware fabrication

-

From small-scale runs to mass production, UCHAMF inserts offer a cost-effective and automation-ready solution to upgrade your back machining operations.

Upgrade Your Machining with UCHAMF Today

Samtec is proud to bring you NOGA MT’s most advanced tooling innovations. If you're searching for high-performance back countersink inserts, hydraulic counterboring tools, or customizable back chamfering solutions, the UCHAMF insert system is your ultimate solution.

Optimize productivity. Enhance precision. Minimize downtime.

Explore the full range of UCHAMF inserts and UX tool-holders today!

Video

DOWNLOAD CATALOGUE

FAQ

1. What is the UCHAMF insert used for?

The UCHAMF insert is specially designed for back countersinking and chamfering applications. When paired with UX tool-holders, it enables precise single-pass machining without rotating the workpiece, improving both efficiency and accuracy.

2. How does the hydraulic mechanism in UX tool-holders work?

The patented hydraulic mechanism utilizes machine coolant (minimum 20 bar / 300 PSI) to activate the insert. This ensures smooth, controlled, and repeatable motion for back counterboring, spot-facing, and countersinking tasks.

3. What industries benefit from the Ultimate Back system?

Ultimate Back is ideal for aerospace, automotive, medical device manufacturing, and electronics—industries that demand precision, repeatability, and high-performance machining solutions.

4. Can UCHAMF inserts be customized?

Yes. UCHAMF inserts are available in standard (82°, 90°) and semi-standard configurations. Options include various coatings, chip-formers, and corner radii, based on your machining requirements.

5. Are the UX tool-holders and UCHAMF inserts compatible across all sizes?

Tool-holders and inserts must be matched by series (e.g., B, C, D, etc.) based on the pilot hole size. Each series corresponds to specific dimensions and insert compatibility, ensuring optimal performance.

6. What is DURASHIELD and why does it matter?

DURASHIELD is NOGA MT’s premium line of tool-holders that undergo passivation to enhance corrosion resistance and structural integrity. It ensures longer tool life, reduced maintenance, and superior durability under harsh machining conditions.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+