See Other Product

UBURR

UBURR

Overview

UBURR – Advanced Machine Deburring Solutions

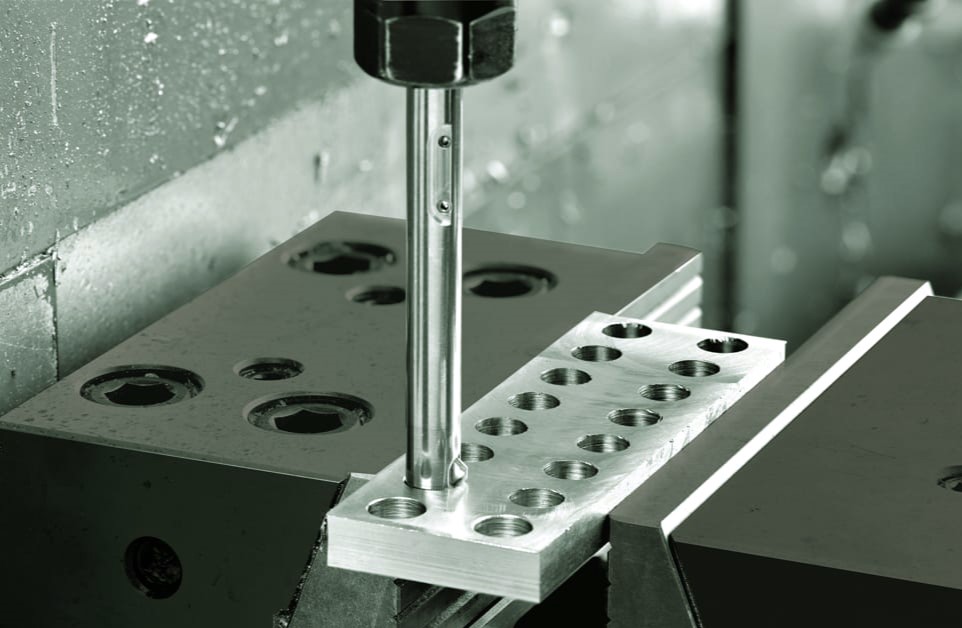

Seamless, Automated Deburring for High-Precision Manufacturing

At Samtec Tools & Accessories Pvt. Ltd., we bring you the next evolution in deburring technology with our NOGA MT UBURR range of tools — precision-engineered to simplify and automate the process of removing burrs from drilled holes. Designed for manufacturers who demand speed, accuracy, and consistency, UBURR sets new benchmarks in automated deburring efficiency, delivering clean, burr-free finishes without the need for manual rework.

Whether you are in the automotive, aerospace, metalworking, or precision manufacturing sectors, UBURR tools help you optimize production cycles and achieve superior component quality.

UBURR Tool-Holders – Engineered for Performance

The UBURR system is built around two core elements:

-

- Precision-Crafted Blades – Available in multiple geometries and chip formers to handle a wide variety of materials and hole diameters.

- Durable Tool-Holders – Made from Precipitation Hardened AISI 17-4 PH steel, offering unmatched rigidity and long service life.

Together, they form a powerful deburring system capable of automatically deburring both the front and back of a drilled through-hole in a single pass, dramatically reducing machining time and enhancing product consistency.

Key Features and Benefits

Automated Excellence

-

-

- One-Pass Deburring: Deburr both sides of a hole in a single operation.

- No Manual Handling: Eliminates part flipping or repositioning.

- Repeatable Accuracy: Achieve consistent results at any production scale.

-

Smart and Efficient Design

-

-

- Plug-and-Play Operation: No blade adjustments needed—just load and run.

- Quick Blade Replacement: Tooling changes are fast and effortless, reducing downtime.

- Protective Blade Geometry: Prevents scratches on surrounding drilled or threaded surfaces.

- Efficient Inventory: Just two blade types cover all hole sizes.

-

Material Versatility

-

-

- Multiple Blade Options: Choose from TiAlN PVD-coated or polished blades with different chip formers.

- Process a Wide Range of Materials: Including steel, aluminum, brass, plastics, and more.

-

Universal Compatibility

-

-

- CNC & Hand Drill Friendly: Designed for use with CNC machines as well as electric hand drills.

- Adaptive Tooling: A single holder supports multiple pilot diameters, reducing inventory and simplifying tool selection.

-

Customizable Configurations

Need a specialized solution? Samtec offers tailor-made configurations to meet specific production requirements, ensuring the perfect fit for your unique operation.

Video

DOWNLOAD CATALOGUE

FAQ

1. What is the UBURR tool used for?

UBURR is designed for automatic deburring of both the front and back of drilled through-holes. It ensures smooth, burr-free finishes without the need for flipping the workpiece or manual rework.

2. Can UBURR be used on CNC machines?

Yes, UBURR is compatible with CNC machines and also works efficiently with electric hand drills, making it a versatile solution for various manufacturing setups.

3. Which materials can UBURR process?

UBURR tools are suitable for a wide range of materials, including steel, aluminum, brass, copper, and engineered plastics. Different blade geometries and coatings are available to match material requirements.

4. Is blade adjustment required during setup?

No, UBURR features a plug-and-play design with no blade adjustments needed. This simplifies setup and ensures consistent results.

5. What makes UBURR different from manual deburring tools?

UBURR automates the deburring process, allowing for faster production, higher precision, and reduced labor costs. It also helps maintain consistency across multiple parts.

6. Are replacement blades available for UBURR?

Yes, Samtec offers a range of replacement blades in different sizes, coatings (such as TiAlN PVD), and chip formers to suit various applications and materials.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+