See Other Product

UFIBER

UFIBER

Overview

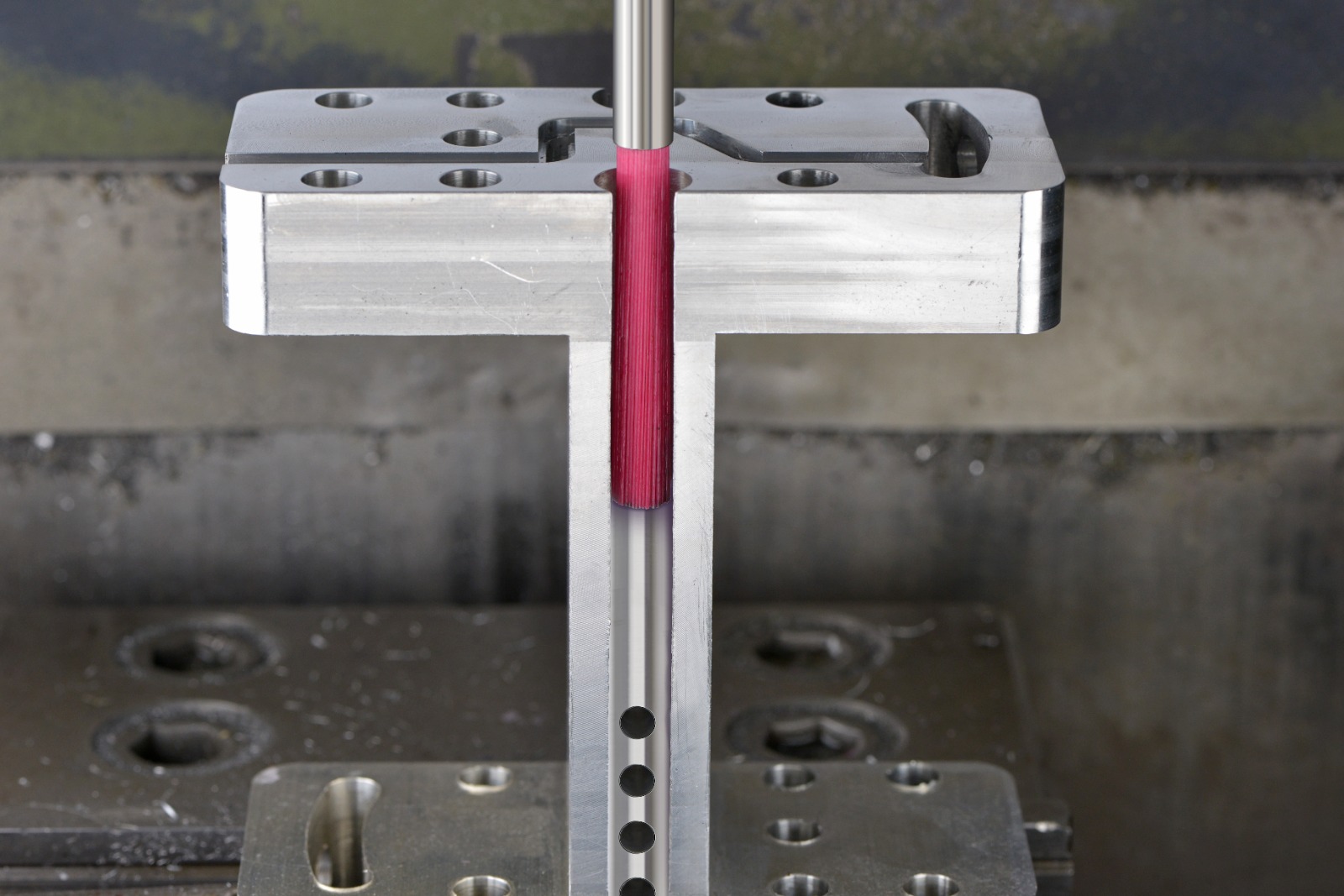

UFIBER – Advanced Ceramic Fiber Brushes for Precision Surface Treatment

NOGA MT introduces UFIBER, a cutting-edge line of advanced ceramic fiber brushes that offer exceptional precision, durability, and versatility for surface treatment applications. Designed with innovative nano-technology, UFIBER brushes cater to the most demanding industrial requirements, delivering superior results in deburring, polishing, and finishing processes.

Nano-Technology Precision for Superior Performance

UFIBER brushes leverage nano-technology to provide superior surface roughness control, exceptional wear resistance, and an extended tool life. Unlike conventional brushes, the ceramic fibers in UFIBER are refined at a nano-scale level, ensuring that each fiber maintains its edge throughout the polishing process. This technological advancement leads to fewer tool changes, longer operation times, and lower production costs, making UFIBER an ideal choice for high-precision applications.

3-in-1 Functionality for Streamlined Processes

UFIBER brushes combine deburring, polishing, and finishing in a single tool, eliminating the need for multiple tools and reducing operational complexity. This 3-in-1 functionality makes UFIBER an efficient choice for industries that demand high-performance surface treatment. By streamlining the manufacturing process, UFIBER brushes not only save time but also reduce costs associated with tool changes and labor.

Versatile Applications Across Industries

The versatility of UFIBER brushes makes them perfect for a wide range of applications, including surface polishing, inner diameter polishing, and small point polishing. Whether you're working on complex geometries or hard-to-reach areas, UFIBER brushes deliver consistent and reliable results. Their ability to handle various materials—such as aluminum, stainless steel, composites, copper, and even hardened materials—ensures that UFIBER brushes are a go-to solution across multiple industries.

UFIBER is highly suitable for applications in the automotive, aerospace, and medical industries. In the automotive industry, UFIBER brushes are ideal for deburring and finishing engine components and transmission parts, ensuring smooth finishes and high precision. In aerospace, they meet stringent safety and performance standards for aircraft components. In the medical field, UFIBER brushes provide smooth, polished finishes on surgical instruments and implants, which are critical for functionality and safety.

Automation-Ready for Modern Manufacturing

UFIBER brushes are compatible with CNC machines and robot arms, making them perfect for automated manufacturing environments. The brushes' ability to maintain consistent grinding power and stability under high-speed conditions supports automation in deburring and tool mark removal, reducing manual labor and enhancing overall production efficiency.

Key Benefits of UFIBER Brushes

-

- Nano-Technology: UFIBER brushes feature nano-bonded ceramic fibers for exceptional wear resistance, extended tool life, and precise surface finishes.

- Extended Tool Life: Thanks to better control over spreading and strong polishing power, UFIBER brushes last longer than traditional abrasive brushes, reducing the frequency of replacements.

- Time Efficiency: With 60 times more grinding power and a 20% reduction in processing time, UFIBER brushes ensure faster production cycles and lower overall costs.

- Stable Grinding Power: UFIBER brushes maintain consistent grinding power, even under high RPM conditions, making them ideal for high-speed automation.

- Superior Surface Finish: The brushes deliver finer surface finishes with reduced polishing scratches, outperforming traditional nylon brushes or ceramic bristles that rely on micro-bond technology.

A Wide Range of Grits for All Applications

UFIBER bristles are available in 10 different grits, ranging from #150 to #6000, allowing them to handle various materials and surface treatment needs. Whether you’re working on soft or hard materials, UFIBER brushes ensure reliable performance across a wide range of burr conditions and applications.

Applications in Key Industries

-

- Automotive Industry: Deburring and finishing engine components and metal surfaces.

- Aerospace: Precision surface treatment of aircraft components for safety and performance.

- Medical Devices: Polishing and finishing surgical instruments and implants.

- General Manufacturing: Suitable for various materials including metals, plastics, and composites.

Video

DOWNLOAD CATALOGUE

FAQ

1. How does nano-technology improve UFIBER performance?

Nano-technology refines the grain structure of each fiber, allowing UFIBER brushes to maintain their edge longer, deliver consistent results, and offer superior wear resistance. This leads to smoother finishes and longer tool life compared to conventional brushes.

2. What materials can UFIBER brushes be used on?

UFIBER brushes are compatible with a wide range of materials, including aluminum, copper, stainless steel (SUS), carbon steel, FRP (composites), and hardened materials, making them suitable for diverse industrial applications.

3. Can UFIBER brushes be used in automated manufacturing systems?

Yes. UFIBER brushes are automation-ready and compatible with CNC machines and robotic arms, enabling seamless integration into modern automated production lines.

4. What are the advantages of UFIBER over traditional abrasive brushes?

UFIBER offers several advantages:

-

- 3-in-1 functionality (deburring, polishing, finishing)

- Nano-ceramic bristles for higher durability

- Up to 60x more grinding power

- 20% faster processing time

- Superior surface finish with minimal scratches

5. In which industries can UFIBER brushes be used?

UFIBER brushes are ideal for various industries including automotive, aerospace, medical devices, and general manufacturing. They are particularly useful for applications requiring high precision and excellent surface finishes.

6. What grit sizes are available for UFIBER brushes?

UFIBER brushes come in a wide range of grit sizes from #150 to #6000, making them versatile enough to handle different surface conditions and material hardness levels.

7. Are UFIBER brushes cost-effective?

Yes. Thanks to their long tool life, reduced need for tool changes, and faster processing speeds, UFIBER brushes lower overall production costs and improve manufacturing efficiency.

8. Can UFIBER be used for inner diameter and small point polishing?

Absolutely. UFIBER brushes are engineered for versatility, including detailed tasks such as inner diameter polishing and small, intricate surface finishing.

Get in Touch

Copyright © 2025 Samtectools

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+