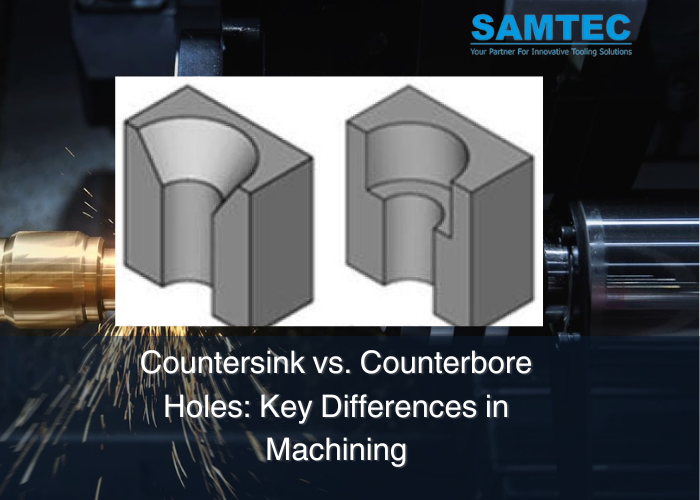

When it comes to machining, countersink and counterbore holes are two essential types that serve distinct purposes. While their shapes may be the most noticeable difference, there are other key aspects worth exploring. Let’s dive deeper into these hole types, their uses, and how they compare.

What is a Countersink Hole?

Countersink holes, indicated by the symbol “⌵,” are cylindrical holes designed to accommodate the angle of a screw, allowing it to sit flush with the surface. Commonly found in woodworking and soft materials, these holes can have various angles, typically ranging from 60° to 120°, with 90° being the most common.

The cone-shaped design of a countersink hole features a widest part known as the "Major Hole Diameter," specifically tailored for the insertion of screws or bolts. The angle of the hole plays a crucial role; a deeper sink enhances the fastener's grip, making joints stronger while minimizing the risk of stripping the material.

Countersinks can be created using a drill and a Phillips-head bit, or with specialized tools. They are particularly advantageous for sheet metal applications, where counterbores may be too costly.

Applications and Benefits

Angle heads find widespread use in industries where precision is critical, such as aerospace, automotive, and medical device manufacturing. These sectors demand high accuracy and consistent quality, making angle heads a crucial component of the machining process.

Key Advantages:

Accessibility: Live tooling can perform various milling processes directly on the lathe, such as edge rounding and squaring, or adding axial and radial features to a component. This eliminates the need to pause the turning process and transfer the part to a CNC mill, thus saving time and improving efficiency. The seamless integration of milling operations into the turning process reduces cycle times and enhances productivity, allowing manufacturers to meet tight deadlines and increase output.

Versatility: Angle heads are versatile tools that come in various sizes and shapes, allowing them to fit different machines and applications. This versatility makes them suitable for a wide range of tasks, from simple drilling to complex milling operations.

Multiple Operations: With angle heads, machinists can perform multiple operations within a single setup. This reduces the number of tool changes required, further boosting productivity and reducing downtime.

Cost-Effectiveness: By streamlining the machining process and minimizing the need for additional setups, angle heads contribute to a more cost-effective production environment. Manufacturers can achieve higher precision with less effort and time, ultimately reducing operational costs.

Why Angle Heads are Important

Angle heads are essential for achieving high precision and efficiency in machining. Their ability to perform complex tasks in hard-to-reach areas makes them invaluable in industries where precision is non-negotiable. By allowing for multiple operations within a single setup, these tools enhance productivity and reduce operational costs.

Manufacturers can choose from a variety of angle heads tailored to their specific needs, ensuring optimal performance for their applications. This flexibility, combined with the inherent advantages of angle heads, makes them a vital component in modern machining.

Conclusion

Samtec Tools is at the forefront of providing high-quality angle heads designed to meet the stringent demands of today's manufacturing industries. With a commitment to innovation and precision, Samtec Tools offers a range of angle heads that cater to various machining needs, ensuring superior performance and cost-effectiveness.

By choosing Samtec Tools, manufacturers can leverage the benefits of advanced angle head technology, achieving unparalleled precision and efficiency in their operations. Whether for aerospace, automotive, or medical applications, Samtec Tools' angle heads are designed to deliver optimal results, making them a trusted partner in the journey towards machining excellence.

In conclusion, angle heads represent a significant advancement in machining technology, offering unmatched precision and efficiency. With Samtec Tools' high-quality angle heads, manufacturers can streamline their processes, reduce costs, and achieve superior results, solidifying their position in a competitive market.

Copyright © 2019 Samtectools

:::| powered by dimakh consultants |:::

Best viewed in IE 10+, Firefox 20+, Chrome , Safari5+, Opera12+